一、产品概述

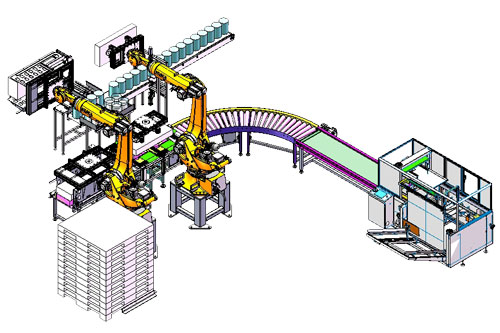

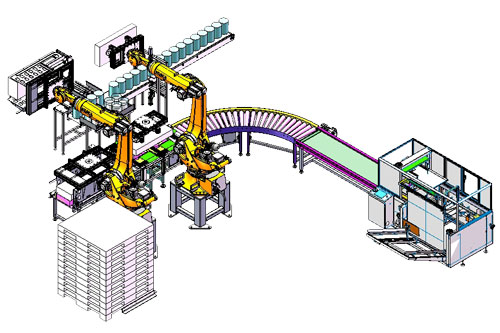

The bucket type material packing, packaging, and palletizing conveyor line is an automated production line designed specifically for cylindrical bucket materials. This production line combines advanced automation technology, robot technology, and intelligent control systems to achieve full automation processing from material packing, packaging to palletizing, significantly improving production efficiency and reducing the investment of human and material resources.

二、应用范围

The bucket type material packing, packaging, and palletizing conveyor line is widely used for automatic packaging and palletizing of cylindrical bucket materials in industries such as chemical, food, and pharmaceutical. Whether it is small-scale production or large-scale production, this production line can provide efficient and stable solutions.

3、 Workflow

- Automatic packing:By using automated robotic arms or conveyor belts, cylindrical barrels of materials are accurately placed into designated boxes.

- Automatic packaging:After the packing is completed, the system will automatically pack the box. The packaging process includes sealing, labeling, reinforcement, and other steps to ensure the safety and stability of the materials during transportation.

- 自动码垛:The packaged boxes are grabbed and palletized by a palletizing robot onto the designated material rack. The palletizing process strictly follows the preset arrangement and stability requirements to ensure the stability and neatness of the material rack.

- Transportation and storage:The material racks that have completed palletizing are transported to the designated storage area through a conveyor line, facilitating subsequent transportation and use.

四、产品优势

- 打造多元化智能生产线:The bucket type material packaging and palletizing conveyor line adopts modular design, which can be flexibly configured and expanded according to different industries and production needs. At the same time, the system supports integration with other intelligent devices to create diversified and intelligent production line solutions.

- Improve production efficiency:The automation of the entire process greatly shortens production time and improves production efficiency. Meanwhile, the stability and reliability of the system ensure the continuity and efficiency of production.

- 降低人力物力投入:Through automated operations, the investment of manpower and material resources has been reduced, and production costs have been lowered. Meanwhile, the intelligent management of the system reduces errors and losses caused by human factors.

- Enhance security:Automated operations reduce manual intervention and lower safety risks. At the same time, the system is equipped with comprehensive safety protection devices and fault alarm systems to ensure safety and stability during the production process.

The bucket type material packaging and palletizing conveyor line provides an efficient and intelligent solution for the automatic packaging and palletizing of cylindrical bucket materials through advanced automation technology and intelligent control systems. This production line not only improves production efficiency and reduces costs, but also enhances safety and stability during the production process, making it an ideal choice for building a diversified intelligent production line.