一、产品概述

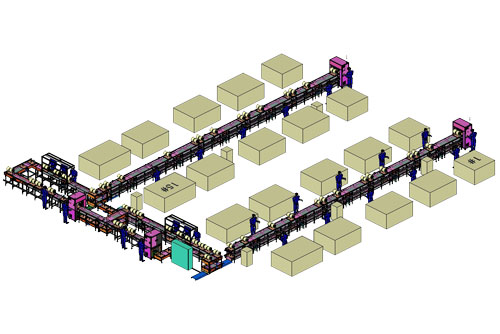

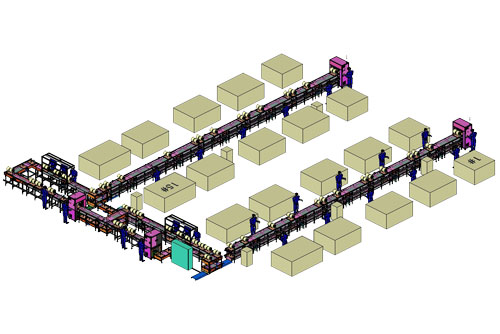

The lithium battery separator inspection and feeding conveyor line is an intelligent production line designed specifically for automatic transmission and testing of lithium battery separators after cutting. This production line has achieved full automation of the entire process of diaphragm cutting, testing, and unloading through automated conveying and testing technology, improving production efficiency and product quality.

二、应用范围

This production line is suitable for automatic transportation, testing, and cutting of lithium battery separators after slitting. By placing the sliced diaphragm on the fixture on the conveyor line, the system can automatically transfer it to the detection line for testing. After the testing is completed, it is automatically transported to the unloading buffer truck, achieving the automation of the entire process.

3、 Workflow

- Loading and transportation:The staff placed the sliced diaphragm on the fixture on the conveyor line. Subsequently, the conveyor line starts and automatically transfers the diaphragm to the detection line. During the transmission process, the system can ensure the stability and safety of the diaphragm.

- automatic detection:When the diaphragm reaches the detection line, the system will automatically perform quality inspection. The testing content includes but is not limited to key indicators such as size, thickness, and appearance. The system adopts advanced detection technology, which can accurately and quickly complete detection tasks.

- Cutting and caching:After the inspection is completed, the system will automatically transport the qualified diaphragm to the unloading buffer material truck. The material truck adopts an intelligent management system, which can display the quantity and status of the diaphragm in real time, making it convenient for the staff to carry out subsequent operations.

四、产品优势

- 降低人力物力投入:Through automated conveying and detection technology, this production line can significantly reduce the investment of manpower and material resources, and lower production costs.

- Improve production efficiency:The automated workflow greatly shortens production time and improves production efficiency. At the same time, the system can ensure the accuracy and consistency of the detection results, improving product quality.

- intelligent management :The unloading buffer material truck adopts an intelligent management system, which can display the quantity and status of the diaphragm in real time, making it convenient for staff to manage and operate.

- 打造多元化智能生产线:This production line has good flexibility and scalability, and can adapt to the production needs of different scales and varieties. At the same time, the system can be integrated with other intelligent devices to form a diversified and intelligent production line solution.

The lithium battery separator inspection and feeding conveyor line provides an efficient and intelligent solution for the production of lithium battery separators through automated conveying and testing technology. This production line not only reduces the investment of human and material resources, but also improves production efficiency and product quality, making it an ideal choice for building a diversified intelligent production line.