一、产品概述

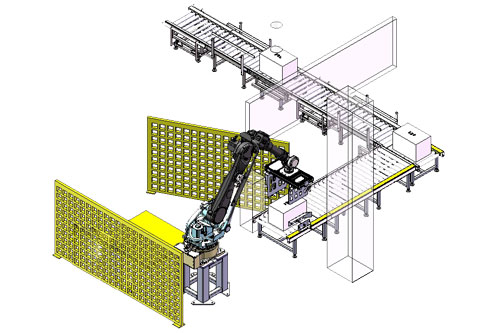

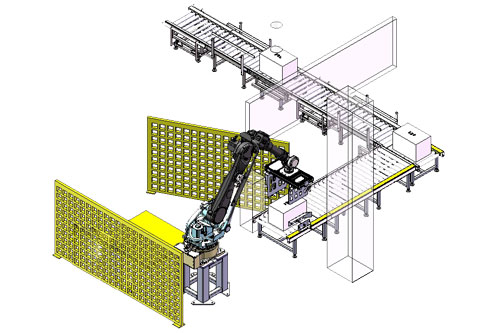

The packing and palletizing conveyor line is an intelligent production line designed for box type materials. It adopts advanced automation technology to achieve full automation processing from box type goods transportation, automatic packaging to precise palletizing. This system not only improves production efficiency, but also reduces the investment of human and material resources, making it an indispensable and important equipment in modern logistics and production fields.

二、应用范围

装箱码垛输送线广泛应用于各类箱式物料的自动打包码垛,包括食品、医药、化工等行业的包装箱。它能够适应不同尺寸、不同重量的箱式货品,满足各种生产和物流需求。

3、 Workflow

- transportation:Box type goods are transported to the designated packaging area through a transport line. The transportation line adopts efficient and stable conveying equipment to ensure the smooth transportation of goods.

- Palletizing:The packaged box goods are transported to the palletizing area. Here, the palletizing robot or robotic arm accurately stacks the goods on the pallet according to the preset palletizing scheme. The palletizing process strictly follows stability requirements and arrangement rules to ensure the safety and neatness of the pallets.

四、产品优势

- 多元化智能生产线:The packing and palletizing conveyor line adopts modular design, which can be flexibly configured and expanded according to different industries and production needs. At the same time, the system supports seamless integration with other smart devices, making it easy to build diversified and intelligent production line solutions.

- Improve production efficiency:By automating the entire process, the packing and palletizing conveyor line significantly reduces production time and improves production efficiency. In addition, the system has efficient conveying and palletizing capabilities, which can meet high-intensity production demands.

- 降低人力物力投入:Automated operations reduce manual intervention and material handling, thereby lowering labor and material costs. Meanwhile, the high efficiency and stability of the system also reduce equipment failures and downtime, further lowering production costs.

- Enhance security:Automated operations reduce the risks and safety hazards of manual operations. In addition, the system is equipped with comprehensive safety protection devices and fault alarm systems, which can stop and alarm in a timely manner in case of abnormal situations, ensuring the safety and stability of the production process.

The packing and palletizing conveyor line provides an ideal solution for automatic packaging and palletizing of box materials due to its high efficiency, intelligence, and safety. Through this production line, enterprises can achieve comprehensive automation and intelligent upgrading of the production process, improve production efficiency and market competitiveness.