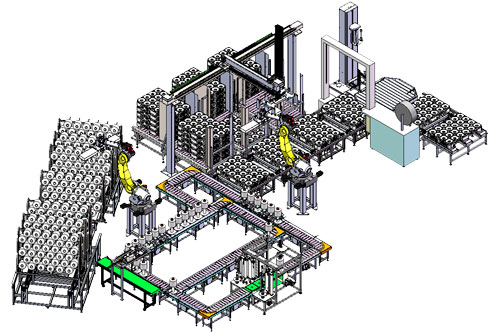

The DTY packing and palletizing transportation line is an intelligent production line designed specifically for factory packing, palletizing, transportation, and other processes. This production line integrates advanced automation technology and robot technology, which can efficiently and accurately complete the entire production process from raw materials to finished products.

The DTY packing and palletizing transportation line is widely used in various factories for packing, palletizing, and transportation, especially in industries such as textiles and chemical fibers. It has significant advantages in packing, palletizing, and transporting products such as silk rolls.

Automatic material retrieval: The wire feeding robot automatically grabs the wire roll from the wire cart and accurately places it on the conveyor line. This step not only ensures accurate grasping of the silk roll, but also greatly improves work efficiency.

Automatic bagging: When the silk roll is transported to the designated position, the equipment will automatically put a packaging bag on the silk roll. This step ensures the cleanliness and integrity of the silk roll during transportation and storage.

Automatic palletizing: After bagging is completed, the wire picking robot automatically picks up the material again and stacks the wire rolls onto the wire roll tray. The palletizing process strictly follows the preset arrangement to ensure the stability and neatness of the wire rolls.

Automatic strapping and winding: After palletizing is completed, the equipment will automatically strip the entire pallet and use a winding machine to wrap the entire pallet. This step not only enhances the stability of the tray and wire roll, but also facilitates subsequent transportation and storage.

Reduce investment in human and material resources: Through automated production, the DTY container stacking and transportation line can significantly reduce the investment in human and material resources, and lower production costs.

Reduce production time: Automated workflows greatly shorten production time, improve production efficiency, and enable enterprises to respond to market demand faster.

Improve production efficiency: The entire production process is completed by robots and automated equipment, reducing errors and delays caused by human factors, and improving production efficiency and quality.

Intelligent monitoring and adjustment: The production line is equipped with an intelligent monitoring system that can monitor the production status in real time and automatically adjust production parameters to ensure the stability and consistency of the production process.

Flexible adaptation: The DTY packing and palletizing transportation line has good flexibility and scalability, and can adapt to production needs of different scales and varieties.

DTY装箱码垛运输线通过先进的自动化技术和机器人技术,为工厂提供了高效、智能、灵活的装箱、码垛、运输解决方案,是提升工厂生产效率和竞争力的理想选择。