一、产品概述

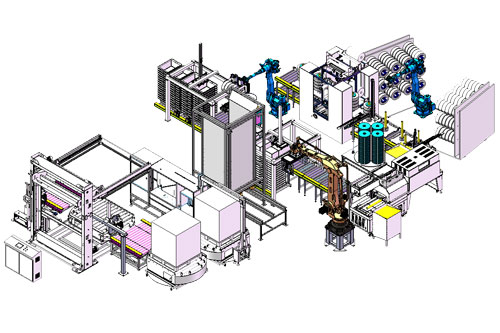

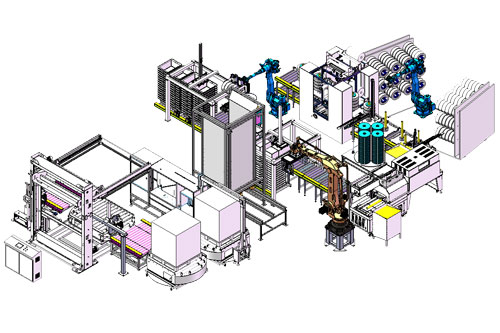

The lithium battery separator packaging palletizing conveyor line is an automated production line designed specifically for the lithium battery separator industry, capable of completing the entire packaging process from bagging, packing to palletizing. Through highly automated equipment and robot technology, this production line provides an efficient and accurate solution for the production of lithium battery separators.

二、应用范围

The lithium battery separator packaging and palletizing conveyor line is mainly used for processes such as bagging, packing, packaging, and palletizing of lithium battery separators. Whether it's large-scale production or small batch customization, this production line can meet your needs.

3、 Workflow

- 自动取料与堆叠:The material retrieval robot automatically grabs the film roll from the material truck and accurately places it on the preset fixture. Subsequently, the equipment automatically stacks the film rolls to ensure stability and neatness of the stacking.

- 自动套袋:After stacking is completed, the production line will automatically wrap the film rolls with packaging bags to ensure their cleanliness and integrity in subsequent processes.

- 装箱与抓取:The packaging robot is responsible for grabbing and loading the completed film roll into the designated box. This process is not only fast but also accurate, greatly improving production efficiency.

- 自动码垛:The palletizing robot automatically stacks the packed film rolls according to the preset arrangement. The palletizing process is stable and efficient, ensuring the neat and stable stacking of goods.

- 整托覆膜缠绕与打包:码垛完成后,生产线会自动对整托托盘进行覆膜缠绕和打包。这一步骤不仅增强了托盘和膜卷的稳定性,还方便了后续的运输和存储。

四、产品优势

- 降低人力物力投入:通过自动化生产,锂电池隔膜包装码垛输送线能够显著减少人力和物力的投入,降低生产成本。

- Improve production efficiency:The entire production process is completed by robots and automated equipment, greatly improving production efficiency and shortening production cycles.

- Reduce production time:自动化的工作流程减少了人为因素的干扰和延迟,使生产更加高效和迅速。

- 打造多元化智能生产线:该生产线具有良好的灵活性和可扩展性,能够轻松适应不同规模、不同品种的生产需求,为锂电池隔膜行业提供多元化、智能化的生产解决方案。

锂电池隔膜包装码垛输送线通过先进的自动化技术和机器人技术,为锂电池隔膜行业提供了高效、智能、灵活的包装解决方案,是提升生产效率和竞争力的理想选择。